SAGD CO2 injection proposed

But cost and corrosion are against him

CO2 injection improves recovery in conventional oil reservoirs. Will it improve recovery in SAGD too?

CO2 injection improves recovery in conventional oil reservoirs. Will it improve recovery in SAGD too?

How do you find innovative SAGD field tests? With AppIntel you can set hit alerts to send you new applications that contain the words thermal bitumen.

In one SAGD pair, this operator proposes to inject CO2 with steam. This reduces steam-oil-ratio (SOR) but also potentially increases bitumen swelling and recovery.

Get the application documents about this operator's CO2 injection scheme in his SAGD project from our self-serve web portal.

Get details of this cool tech Subscribers get them for free?subject=Help me get up to speed on CO2 injection&body=Help me get up to speed on CO2 injection in SAGD. I'm interested in your review of CO2 and acid gas injection in Alberta.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for a review of CO2 and acid gas injection in Alberta.

Reduce SOR -> reduce cost

Reduction of steam-oil-ratio usually indicates a reduction of operating costs. Steam is a costly commodity to generate. When natural gas is very cheap, it might make sense to substitute it for steam as long as recovery doesn't suffer.

CO2 can be even cheaper than gas if it's harvested from boiler flue gas. In this way, CO2 may be a free injectant.

Not free CO2

But CO2 is not a free injectant for this short term pilot. During the test, the operator will buy CO2 from an Alberta CO2 supplier and have it trucked to site. This is a very expensive CO2 source.

CO2 causes oil to swell and increases pressure in the reservoir. CO2 swelling may also discrease bitumen viscosity although this operator doesn't claim this benefit.

CO2 benefits

The operator believes there are four mechanisms that trap CO2 in the reservoir. He lists them and maintains that this could be a good way to reduce greenhouse gases.

In this test, the operator hopes to quantify the mechanisms that trap CO2 in the reservoir. This could pave the way for CO2 sequestration in SAGD. We found this information using AppIntel.

CO2 downside

CO2 is corrosive when mixed with even small amounts of water. Corrosion may attack surface facilities and piplines, well heads, casing and tubing strings. The operator discusses CO2 corrosion attack in his application and how he will mitigate its effects.

Each AER application contains your neighbor's perspective on the exploitation of oil and gas formations. Applications contain more technical data even than SPE papers. Not only can you see implementation of new technology quicker, but you can also see the location it's installed. You can check out actual production response compared to the prediction.

And applications are adjudicated by a very picky regulator who has a stake in a technology's success or failure. This provides better intelligence than adjudication by a panel of engineers who have a passive interest in technology for technology's sake.

SAGD carbon injection.?subject=Sign me up for an AppIntel subscription&body=Sign me up for an AppIntel subscription just for a day.%0D%0A%0D%0AMy Name: __%0D%0AMy Phone Number: ___%0D%0A%0D%0AType of applications __%0D%0ACheck out pricing https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403 803 2500)">Contact us to try AppIntel just for a day.

Tags: Thermal, Heavy Oil

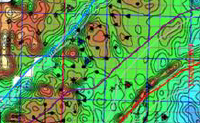

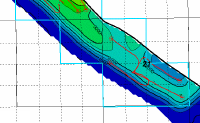

Granger Low 28 Jun 2016

Granger Low 28 Jun 2016

Supercharge 2026 with exploration AI skills that matter

Found a corner shot in thermal scheme

Don't blow the lid

Fracking into a neighboring well causes a blowout

Continuing Canadian thermal innovation doubled oil production

Experimental Propane Solvent co-injection in thermal

Shale in SAGD

How shale much is too much shale? Ask AppIntel AI.

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI shows SAGD type logs

Check out the picks and cap rock

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share